About Our Sustainability

PhilStic Labels Limited (PhilStic) is a people centric company who care very much about the planet our community lives and operates within.

We strive to find better ways to deliver earth friendly products to our customers. But do not wish to green wash, for instance while plastics are the number one public enemy at the moment - there are in fact no glass or steel labels.

Therefore, sustainability within the labelling industry falls into two key areas (a) the disposal of the label after it has served its purpose; or (b) the ability to recycle it together with the packaging it was applied to or separately if removed.

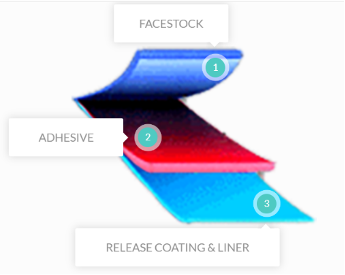

A plain / unprinted label comprises of three main components:

1. The face stock or actual base label material. There are many types and within the supply chain industry which uses billions of labels annually to carry goods globally the most common are: -

(a) Thermal Direct Paper – which contains a heat sensitive coating applied to the label face to allow the label printer to print directly into the label;

(b) Thermal Transfer Paper – which can be paper based or plastic for application onto shrink wrap film.

This is without any ink component, varnish or other finishing on the label. Plus excludes plastic and / or synthetic type label materials.

2. Now to the pressure-sensitive adhesive or glue on the back of the base label material. Pressure-sensitive label adhesives are commonly made from water-based acrylic adhesives, with a smaller volume made using solvent-based adhesives and / or hotmelt adhesives.

There are many other specialty adhesive types such as heat sensitive which comes off in a bottle wash, cryogenic which can go down to minus -200 degrees Celsius for lab sample applications, oil resistant tyre adhesive labels and so on.

In short, the adhesive is a chemical which is not usually land fill or recycle friendly.

3. A release liner is a paper or plastic-based film which is usually applied during the base label material manufacturing process and is used to prevent the sticky surface side of one label from prematurely adhering to the face of another label.

Release liners commonly use a release agent which contains silicone, or other similar coatings, because they have a low surface energy.

Globally there are between 400 and 500 companies involved in making or dealing with release liner products on an industrial scale. There are currently two release liner recycling schemes in place, but these involve shipping used release liner to either Europe or India. These are not free schemes and come with a healthy disposal fee and also require a significant carbon footprint to ship the liners around the world.

While these schemes aid the liner from going to our landfill, PhilStic as a people centric company who care very much about the planet our community lives and operates within are always watching for new developments in eco-centric base materials. We present these to our customers as they are introduced.

For your sustainable label application, please talk to one of our sales team because as you can see above one size does not fit all.

The PhilStic sales team will work through the best option sustainable solution available for you as at today.